Railway power remote control terminal equipment (RTU) is an important component of railway power remote control system, which collects and controls on-site data for power supply facilities of communication, signal and other systems.

In order to improve the safety, reliability, and flexibility of railway power supply systems, standardize and unify the technical requirements for the composition and function, technical requirements, testing and inspection rules of railway power remote terminal equipment, China Railway Corporation has formulated TJ/GD015-2015 "Interim Technical Conditions for Railway Power Remote Terminal Units (RTUs)", which was implemented in 2015. Railway power remote control terminal devices (RTUs) are divided into two types according to their purposes: box transformer power remote control terminal equipment (box transformer RTUs) and low-voltage substation power remote control terminal equipment (low-voltage RTUs). There are two types of low-voltage RTUs: centralized and distributed. When using centralized low-voltage RTUs, each low-voltage cabinet is equipped with a set of remote terminal equipment; When using distributed low-voltage RTUs, each low-voltage circuit is equipped with a remote terminal device. Compared to centralized low-voltage RTUs, distributed low-voltage RTUs have the characteristics of convenient wiring, low construction difficulty, and simple maintenance, and are widely used.

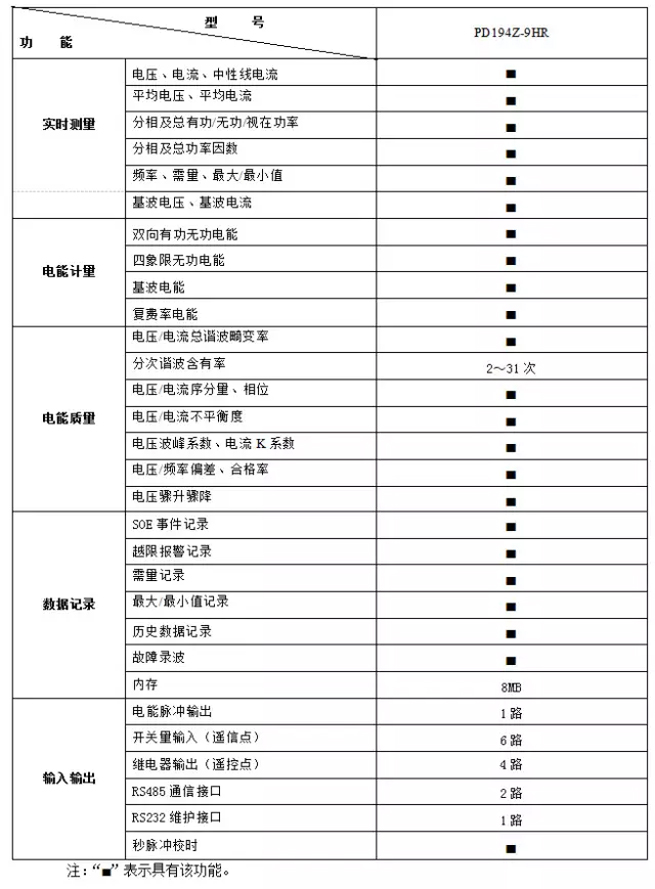

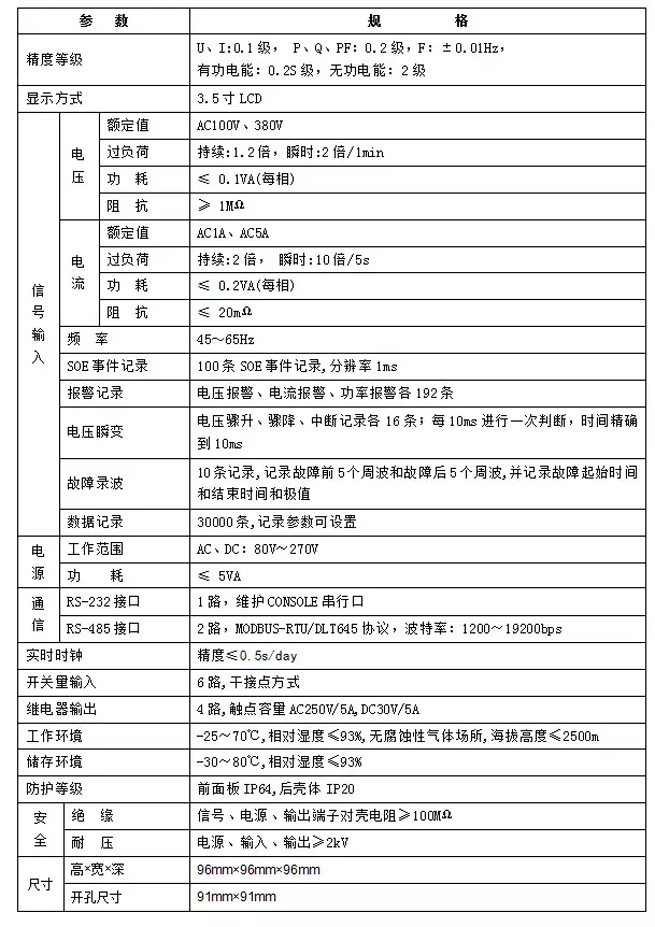

Distributed low-voltage RTU, as a proprietary power equipment in railway power supply and distribution systems, has special requirements compared to multifunctional power instruments, such as large capacity waveform recording data, accurate to 1ms switch position SOE, support for second pulse timing, and maintenance of the CONSOLE serial port.

I would like to recommend a product to you this time, model PD194Z-9HR. This product is a distributed low-voltage RTU developed by SF Electric for railway power supply and distribution systems in accordance with the TJ/GD015-2015 standard.

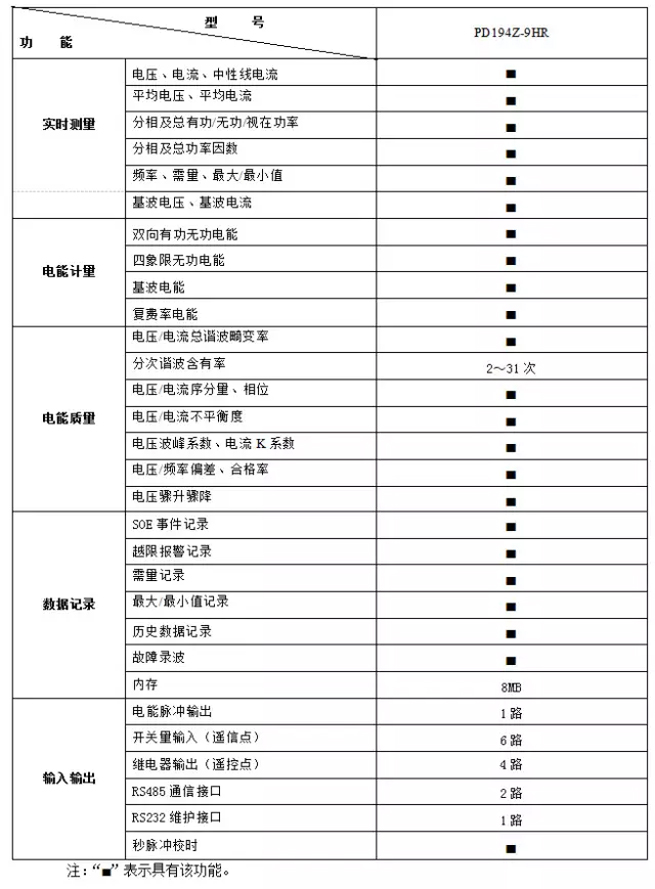

Product Features

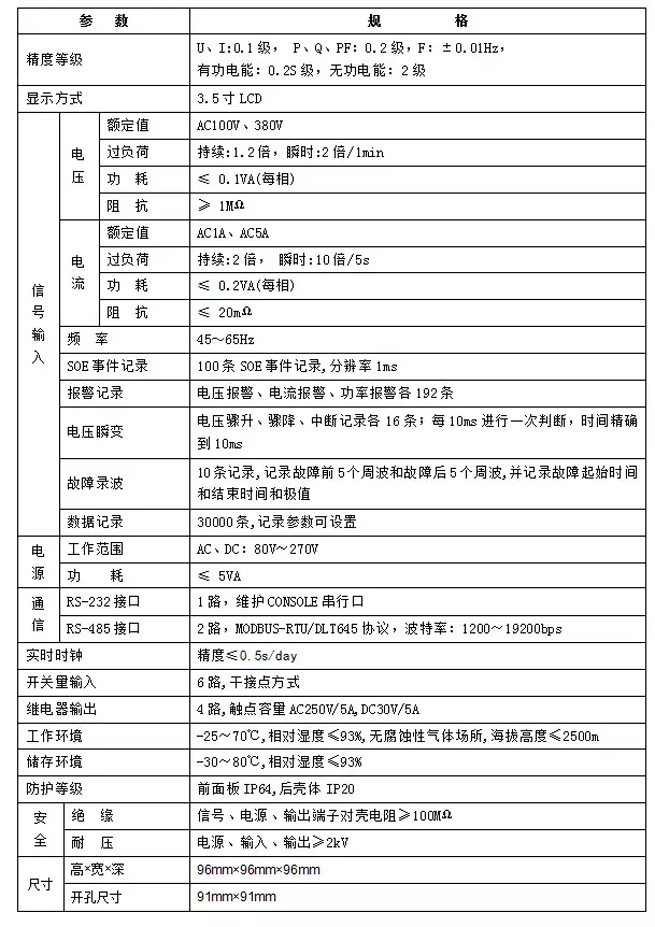

Technical Parameter

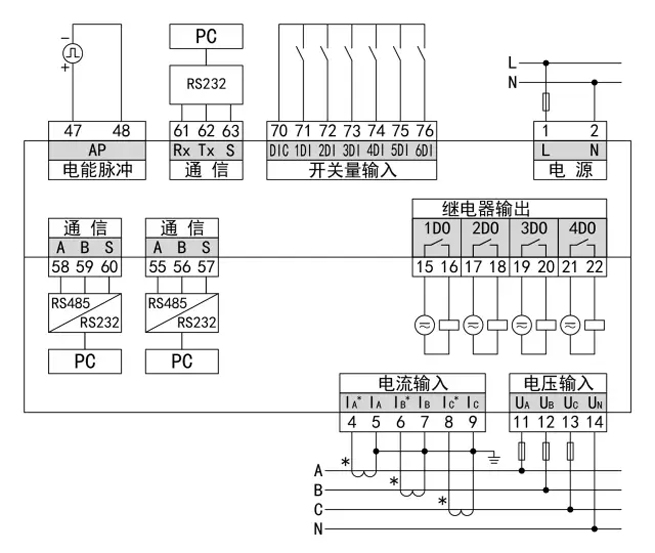

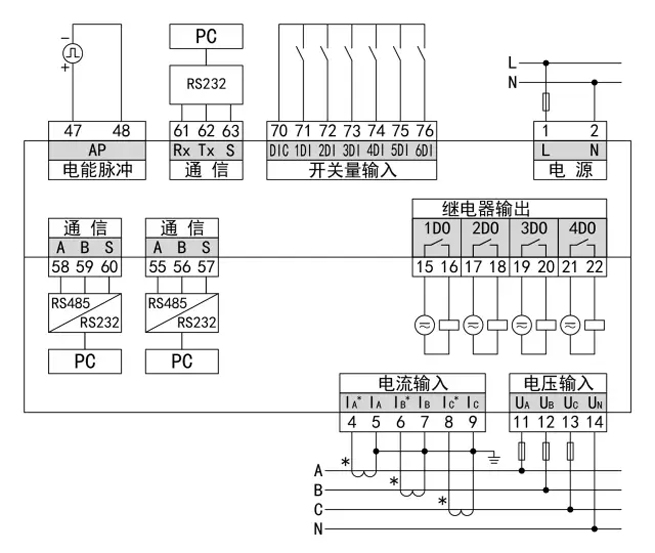

Typical Wiring

CN

CN EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  ar

ar  vi

vi  tr

tr  th

th