With the rapid development of China's economy, people are paying more and more attention to the fire safety of buildings. Fire automatic alarm and automatic fire extinguishing systems have become important components of buildings, and the stability of the power supply quality of fire equipment is particularly important. On December 30, 2011, the national standard GB28184-2011 "Fire Equipment Power Monitoring System" was promulgated. This standard stipulates that the fire equipment power monitoring system is "a monitoring system used to monitor the working status of the fire equipment power supply, and can issue an alarm in the event of overvoltage, undervoltage, overcurrent, and other faults in the power supply." It also mandatorily stipulates the basic functions, testing and inspection rules of the fire power monitoring system.

The SCK800 fire protection equipment power monitoring system developed by SF Electric successfully passed the testing and certification of the Shenyang Fire Research Institute of the Ministry of Public Security in June 2015.

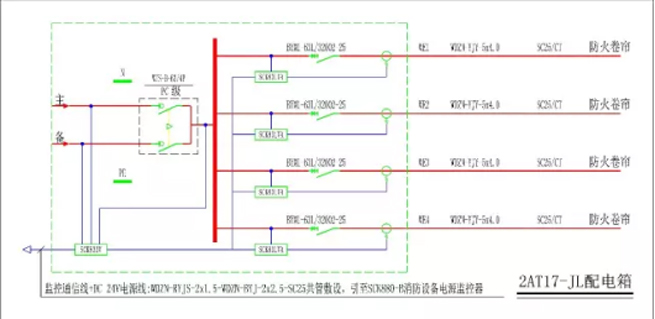

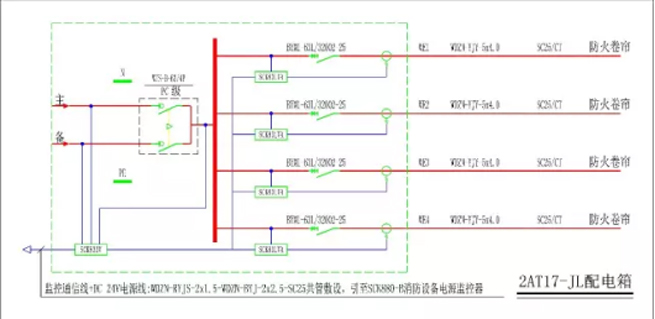

The SCK800 fire equipment power monitoring system consists of an SCK880 fire equipment power status monitor, an SCK81 series single-phase voltage/current signal sensor, an SCK83 series three-phase voltage/current signal sensor, and a residual current temperature module. The voltage/current signal sensor monitors the voltage, current, switch status, and other related equipment power information of the fire equipment power supply in real time. When faults such as open circuit, short circuit, overvoltage, undervoltage, phase loss, phase mismatch, and overcurrent are detected in the power supply equipment, the signal sensor sends an alarm on site and sends information to the fire equipment power status monitor. The fire equipment power status monitor sends an audible and visual alarm and records the event information, thus achieving decentralized monitoring and centralized management.

System structure

The SCK800 fire equipment power monitoring system adopts a three-layer structure, consisting of a fire equipment power status monitor configured in the fire monitoring room, a voltage/current signal sensor installed in the fire equipment distribution box, and fire electrical equipment. The system adopts a low-power 32-bit microprocessor for signal processing, and is networked through the XY-CN bus, supporting bus connection, star connection, and other methods, making construction simple; The system is powered by DC 24V voltage, which is safe and reliable; The fire equipment power status monitor has RS-485 and RJ45 Ethernet interfaces and provides Modbus RTU and Modbus TCP communication protocols to the outside world, making it easy to connect to other standard systems.

System function

Display fault circuit and sound and light alarm, support silencing, self check function, and reset function;

Detect the power interruption fault of the monitored fire-fighting equipment;

Detect short circuit and open circuit faults in the connection wires between the monitor and the sensor;

Detect overvoltage faults where the monitored power supply voltage value is greater than 110% of the rated voltage;

Detect undervoltage faults where the monitored power supply voltage value is less than 85% of the rated voltage;

Detect the occurrence of phase failure, phase mismatch, and overload faults in the monitored power supply;

Detect open circuit and short circuit faults in the connecting wires between the charger and the backup power supply of the monitor's own backup power supply;

Detect the undervoltage fault of the main power supply of the monitor itself;

Faults can be queried and printed in real time;

Two relay control outputs;

Secondary operation permission settings for easy management;

Equipped with backup power supply, ensuring continuous power supply within 8 hours.

Design examples

CN

CN EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  ar

ar  vi

vi  tr

tr  th

th