Lanzhou New Area Shuangliang Thermal Power Co., Ltd. was established on July 31, 2013, wholly owned by Gansu Shuangliang. According to the special heating plan of Lanzhou New Area, the company is responsible for the construction and operation management of the centralized heating project in the area south of Wei 16th Road in Lanzhou New Area. The construction and operation of this project can maximize the restrictions on gradually settling enterprises to set up scattered coal-fired small boiler rooms, thereby reducing environmental pollution to the urban area, improving environmental hygiene, improving winter air quality, improving heating quality, and achieving the utilization of low-quality fuel and waste.

The total length of the Shuangliang heating pipeline network project in Lanzhou New Area is about 2 × 38KM. Gansu Branch has undertaken the construction of two sections of the heating pipeline I and V in the new area, with a total pipeline length of 2 × 17.9KM, mainly distributed on the main roads of the new area, such as Jing12th Road, Wei6th Road, Wei8th Road, and Wei9th Road. The diameter of the pipeline is within Φ 159 × 5~ Φ Within the range of 1220 × 14, the designed operating pressure is 1.6MPA, the water supply temperature reaches 130 ℃, and the return water temperature reaches 70 ℃. The excavation depth of the pipe trench is 3.5-3.8 meters, with a width of 5.5 meters for the upper part and 3.2 meters for the lower part. The hot water supply and return pipes are laid side by side with a center spacing of 1.5 meters.

According to China Heating Information Network, the project belongs to municipal engineering and livelihood engineering, with strong professionalism, high quality requirements, short construction period, involving multiple departments, and difficult coordination. The project department will carry forward the work style of "not delaying or slacking off a day", face difficulties, ensure the overall requirements of quality, safety, and construction period, fulfill the solemn commitment to the owner, and ensure the smooth heating of Lanzhou New Area.

2. Overall project situation

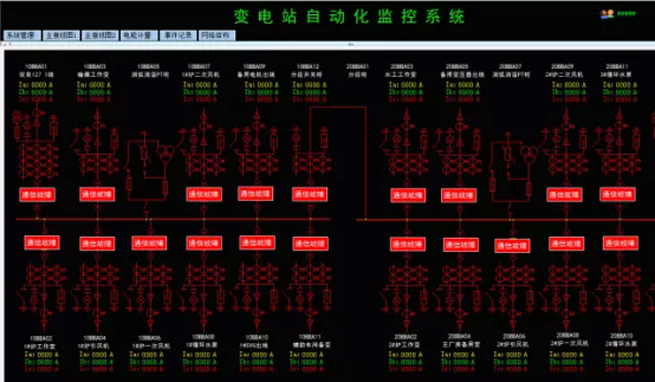

The core of the Shuangliang Thermal Monitoring Center in Lanzhou New Area for real-time monitoring and alarm of substations is the Svere-PMS power monitoring software platform provided by Jiangsu Sifel Electric Co., Ltd. It relies on the S3100 series front-end communication management machine provided by Sifel to achieve a series of functions such as real-time data collection of all distribution cabinets, immediate reminder of operation alarms/accidents (supporting alarm SMS reminders), and historical data recording.

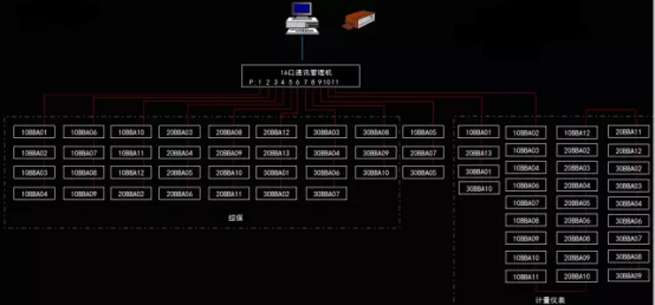

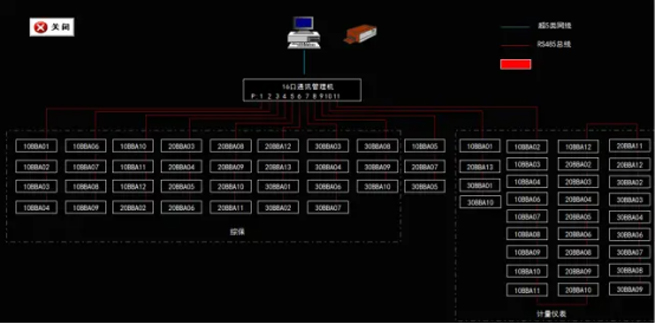

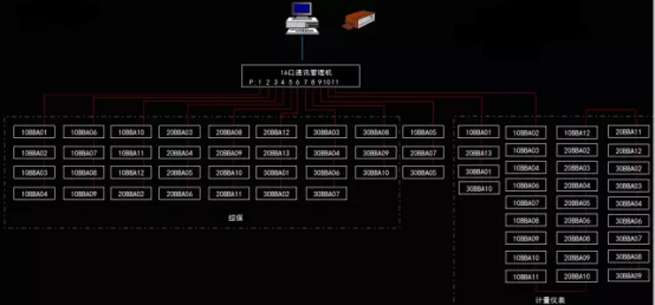

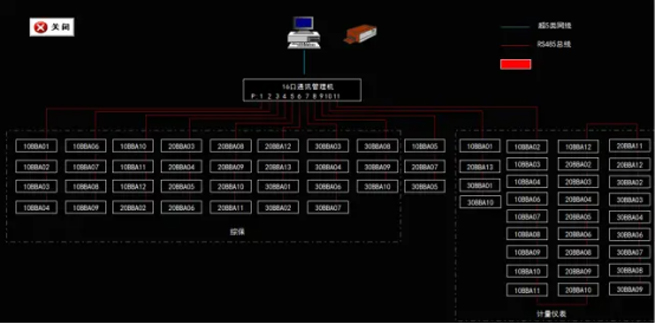

3. Network topology structure

The Shuangliang Thermal Power Monitoring System in Lanzhou New Area adopts a three-layer structure, consisting of a power monitoring host configured in the fire monitoring room, an S3100 series front-end communication management machine, multifunctional instruments installed in the distribution room, and a microcomputer comprehensive protection device. The S3100 series front-end communication management machine has RS-485 and RJ45 Ethernet interfaces and provides Modbus RTU and Modbus TCP communication protocols externally, making it easy to connect to other standard systems.

4. Monitoring scope and functions

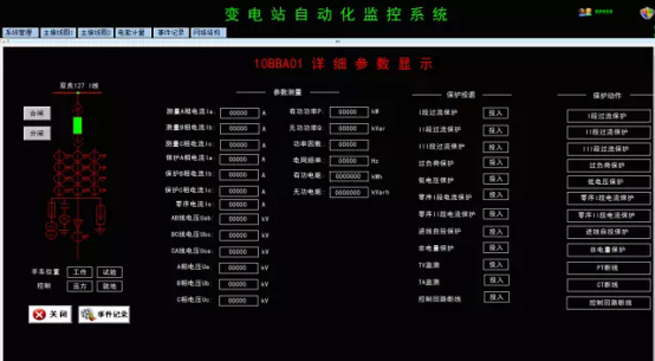

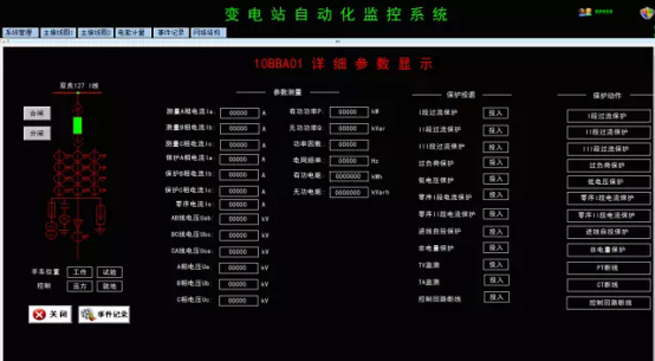

This system mainly monitors the 10kV substation of end users, achieving real-time monitoring of online alarm information, display and record of data and status, and responding to alarm accidents in each substation within 5 minutes to minimize user labor costs and power outage time.

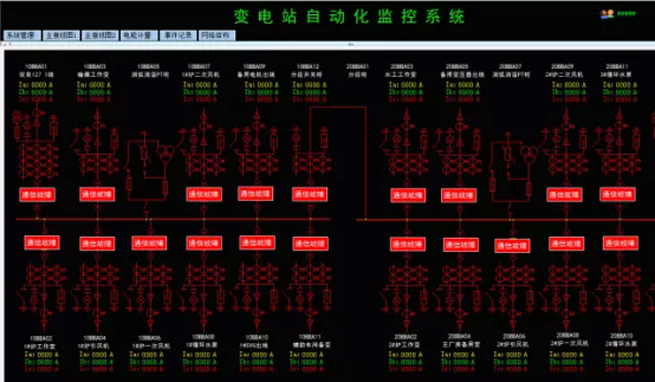

5. Real time monitoring

Capable of displaying monitoring data and protection status of all circuits in the substation in a single system diagram format. And distinguish the switch status of each circuit in real time.

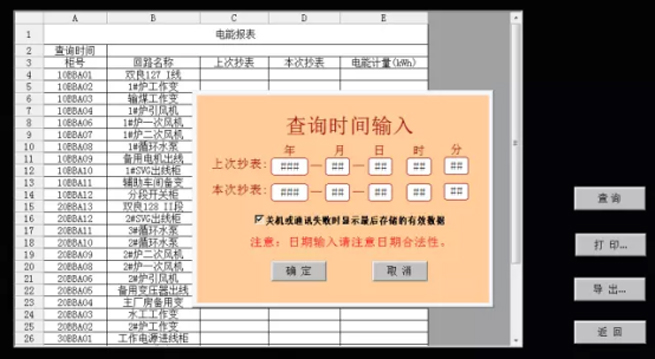

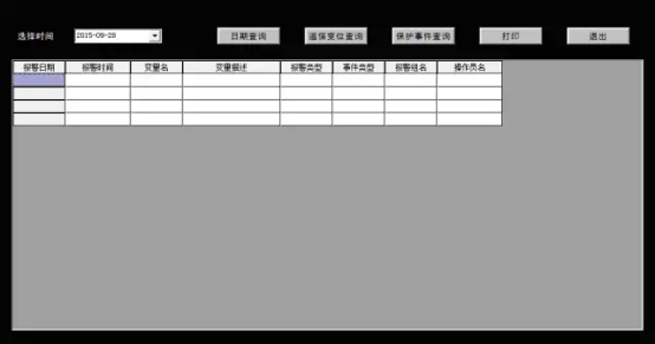

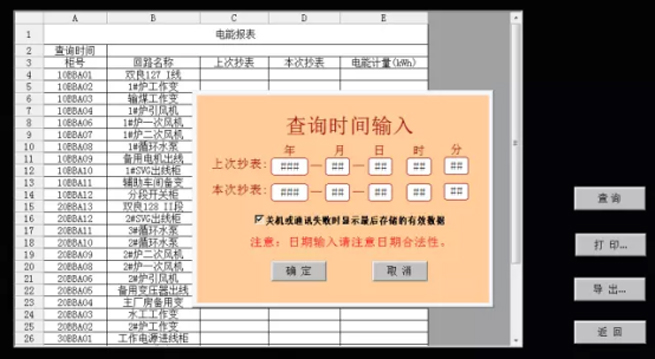

6. Electricity inquiry

By querying historical data through reports, it is possible to query electrical energy data and protection records.

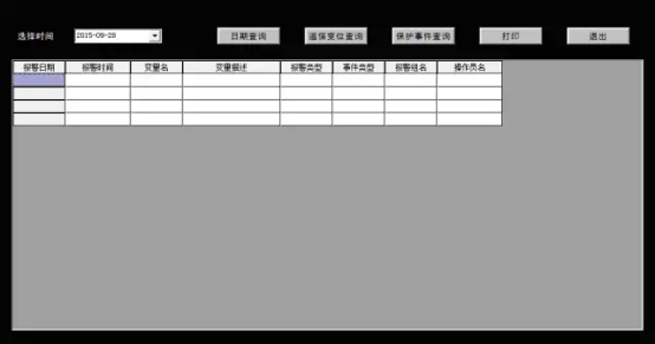

7. Alarm information

Pop up display of real-time alarm accident signals to remind duty personnel, ensuring that they can respond to all alarm accident information in a timely manner.

8. Communication status

Real time display of the communication status between the monitoring devices of each distribution cabinet and the front-end communication management machine.

CN

CN EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  ar

ar  vi

vi  tr

tr  th

th