The First Affiliated Hospital of Zhengzhou University was founded in September 1928. Its predecessor was the former Affiliated Hospital of National Henan University School of Medicine. In 1958, it moved from Kaifeng to Zhengzhou and was renamed the First Affiliated Hospital of Henan Medical University. In 1985, it was renamed the First Affiliated Hospital of Henan Medical University. In 2000, it was merged into the new Zhengzhou University and officially named the First Affiliated Hospital of Zhengzhou University. It has been successively awarded the honorary titles of "Grade III Grade A Hospital", "National Baby Friendly Hospital", "National Top 100 Hospital", "National Advanced Grass roots Party Organization for SARS Prevention and Control", "exemplary organization of Hospital Management Year in Henan Province", etc.

The First Affiliated Hospital of Zhengzhou University is one of the few modern comprehensive hospitals in China that integrates teaching, scientific research, medical treatment, prevention, health care, and rehabilitation. It has strong treatment capabilities, international exchange capabilities, and a high level of scientific research. The target hospital has 10000 beds and an annual outpatient volume of about 4 million people. It is known as the "Central Plains Medical Aircraft Carrier" and can be called the world's largest hospital.

Project overview:

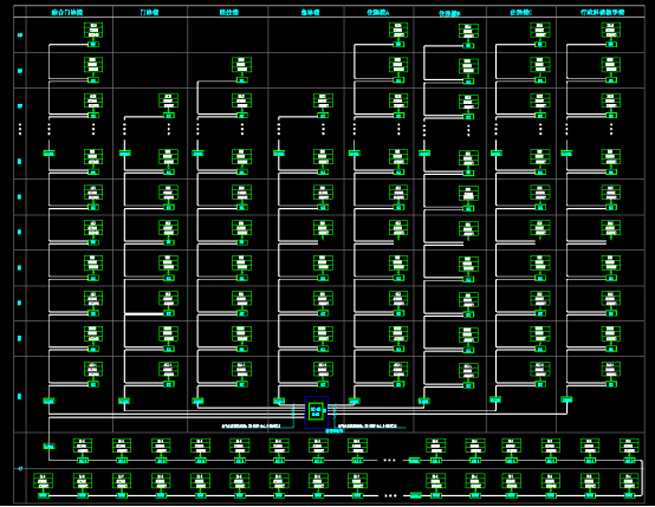

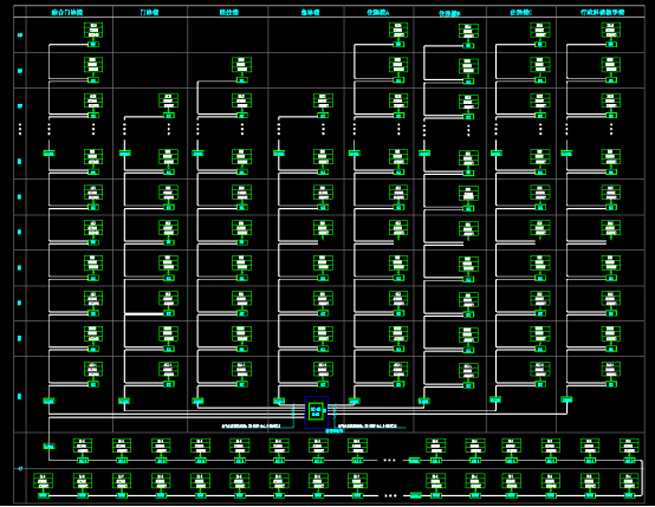

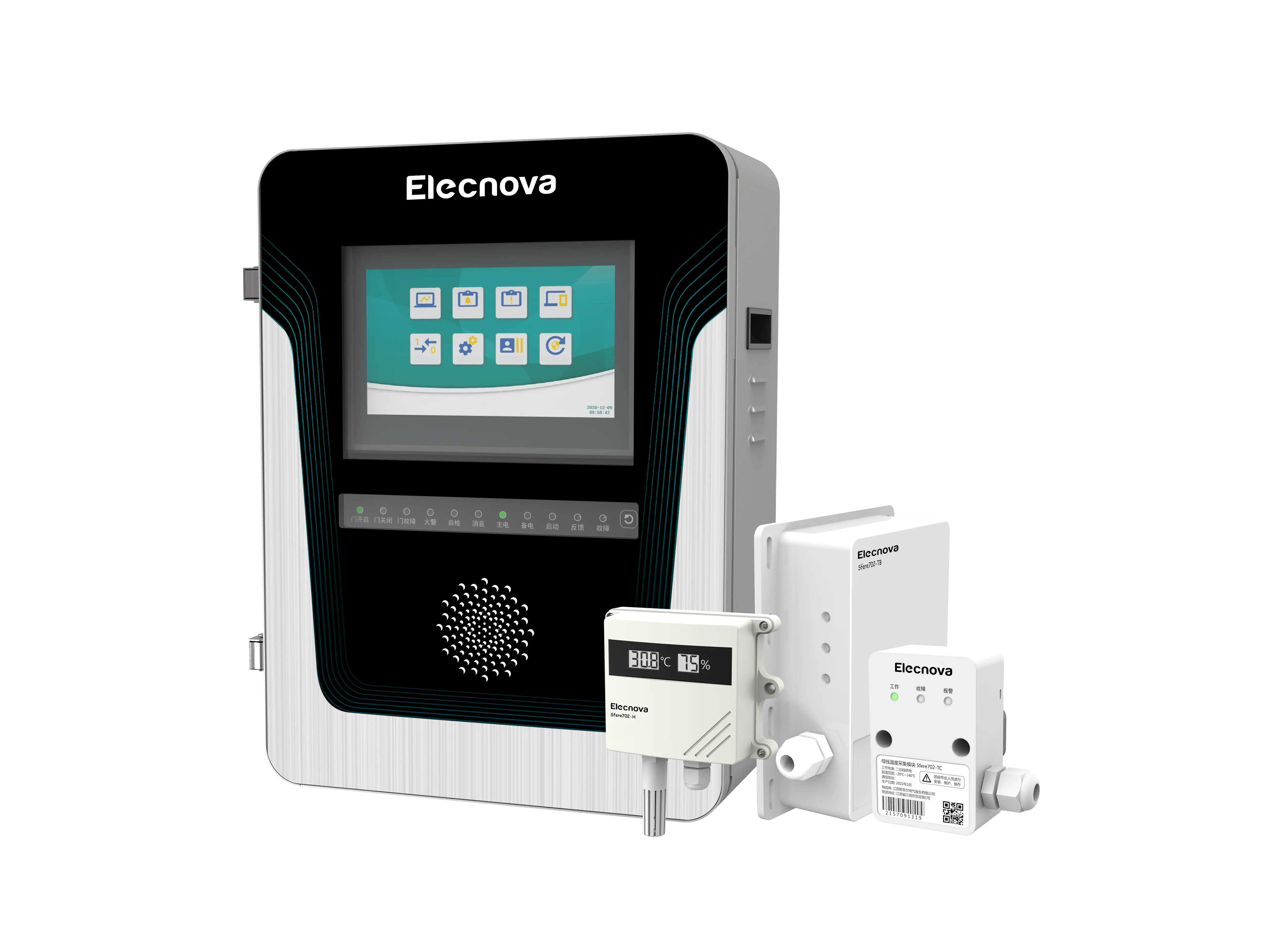

Due to the increasing number of large-scale equipment in hospitals, new buildings often face fire hazards due to adjustments to departments, changes in original design purposes, and power overload. In addition, the hospital has a large flow of people, centralized equipment, a large number of flammable and explosive materials such as pressure vessels, chemical reagents, bedding and paper, dense buildings, interconnected passages, and a majority of vulnerable groups (patients). Once a fire occurs, it may cause significant property damage and casualties. Realizing these, the First Affiliated Hospital of Zhengzhou University has built an SCK600 electrical fire monitoring system: electrical fire monitoring detectors SCK600Y and SCK600YT are installed in the distribution boxes of eight buildings including the comprehensive outpatient building, outpatient building, medical technology building, emergency building, inpatient building A, inpatient building B, inpatient building C, and administrative research and teaching building, as well as in the important circuits in the basement. The detectors transmit the leakage current and temperature parameters of each circuit to the electrical fire monitoring unit SCK630 through a two bus method, and the monitoring unit then transmits the data to the main unit SCK680-B in the fire control room. Relevant management personnel can achieve centralized control and management on the monitoring unit and monitoring host.

When the relevant parameters in the circuit are abnormal, the monitoring equipment emits sound and light alarms, indicating the alarm location. At the same time, the on-site detector emits light alarms and control signals to remind management personnel to investigate or replace hidden danger lines, reducing the risk of fire caused by electrical reasons.

This project uses a total of 5 SCK680-B1008 electrical fire wall mounted monitoring hosts, 136 SCK630 electrical fire monitoring units, 1117 SCK600Y electrical fire residual current monitoring detectors, 1117 SCK600YT electrical fire temperature monitoring detectors, and 1117 NTC temperature sensors.

System structure:

The SCK600 electrical fire monitoring system adopts a three-layer distributed design of equipment layer, communication layer, and management layer, achieving decentralized control and centralized management.

System composition and functions:

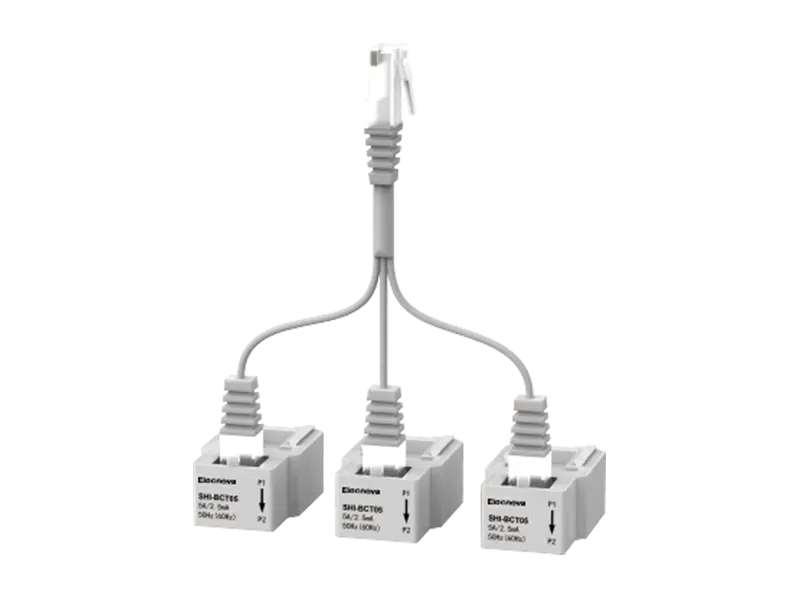

Install a residual current monitoring detector SCK600Y and a temperature measurement monitoring detector SCK600YT on each circuit that needs to be tested, monitor the residual current and temperature values of each circuit in real time, and transmit the data to the monitoring unit SCK630 and the host SCK680-B1008 through the secondary bus. The detailed circuit name, number, and various functional buttons are displayed on the main interface.

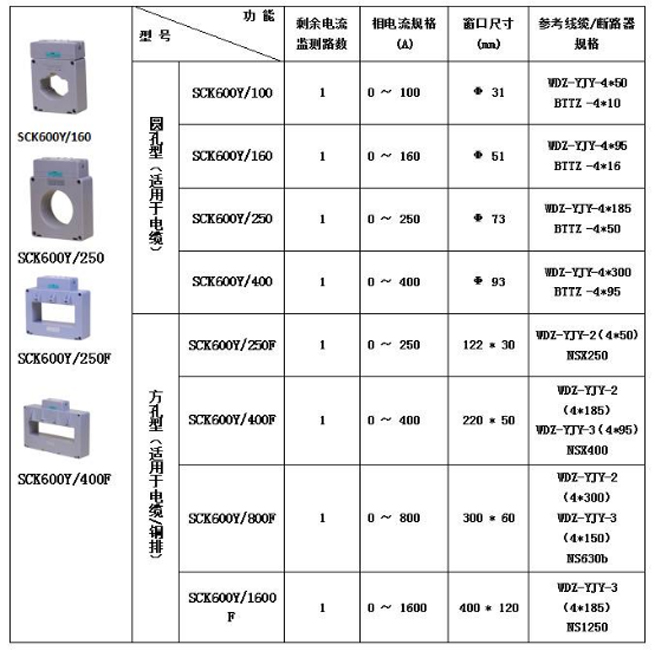

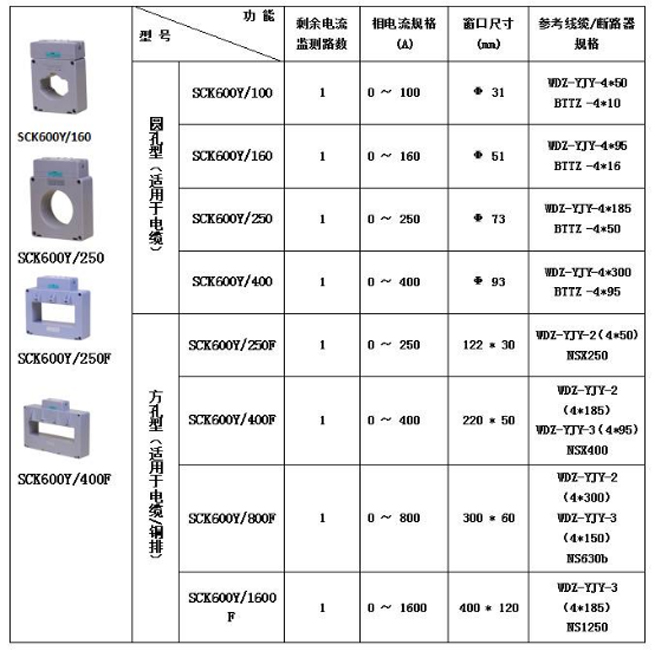

According to the different specifications of the cables and the rated current of the circuit, different specifications and models of the electrical fire residual current monitoring detector SCK600Y need to be selected. The specific specifications and dimensions are shown in the table below:

The SCK600YT temperature measuring electrical fire monitoring detector is connected to the electrical fire monitoring equipment or monitoring unit through the fire protection secondary bus, achieving timely reporting of alarms and faults; Combined with NTC temperature sensors, it can measure 4 temperature signals in real-time, with a temperature measurement range of -10~150 ℃. The bright LED light indicates the operating status of the detector, and TH-35-7.5 standard guide rail installation.

Install a monitoring unit SCK630 with approximately 25 detectors in the comprehensive outpatient building, outpatient building, medical technology building, emergency building, inpatient building A, inpatient building B, inpatient building C, administrative research and teaching building, and basement for on-site monitoring within a small area.

The SCK630 electrical fire monitoring unit comes with one downlink fire protection secondary bus; Can monitor real-time data and alarm signals of up to 32 SCK600Y electrical fire monitoring detectors downwards; Equipped with sound and light alarm function and displaying alarm location, with Chinese prompts to help users quickly and accurately determine the alarm location; Can record more than 10000 alarm event records, supporting sound attenuation, self check function, and reset function; Fully electronic coding, can be rewritten on-site through monitoring equipment or buttons, and engineering debugging is simple and reliable.

Optional configuration with 1 RS485 communication channel, which can be connected to relevant collection equipment for networking of large-scale electrical fire monitoring systems;

At the same time, it can be equipped with 1 leakage circuit and 4 real-time temperature monitoring circuits;

Communicate with monitoring equipment through the fire protection secondary bus to achieve timely reporting of alarms;

Can be used as an isolator and can increase the communication distance of the bus.

Install wall mounted host SCK680-B1008 in the fire control room for centralized control and management of the entire project.

Working power supply: Main power supply: AC220V 50Hz (with a range of 85% to 110% allowed); Backup power supply: In case of low voltage or power outage of the main power supply, maintain the working time of the monitoring equipment for ≥ 4 hours.

Communication method: Fire protection two bus method: Pulse 24V non-polar two bus, dedicated communication protocol to achieve alarm interruption reporting, transmission distance ≤ 1.5km. RS485 bus mode: Modbus RTU communication protocol, half duplex mode, transmission distance of 1.2km (communication transmission distance can be extended through repeaters).

Monitoring alarm: The monitoring equipment receives real-time monitoring alarm signals from the detector and emits sound and light alarm signals within 30 seconds, indicating the alarm location, recording the alarm time, and maintaining it until manually reset. The alarm sound signal can be manually eliminated, and it can be restarted when there is another alarm signal input.

Fault alarm: When there is a communication failure between the monitoring equipment and the detector, undervoltage of the main power supply, or failure of the backup power supply, the monitoring equipment will indicate the fault information, emit a fault prompt sound, and light up the fault LED indicator light.

Users can achieve the following functions on the host

Real time monitoring

The system monitors the residual current and temperature values of each circuit in real time, and displays detailed circuit name and number content as well as various functional buttons on the main interface.

Alarm settings and prompts

The system supports remote setting of residual current and temperature alarm values, as well as various circuit information and status. When an alarm occurs in the circuit, the system emits an audible and visual alarm signal, and at the same time, the interface emits a significant color change, automatically recording detailed sequence of events. The number of event records is ≥ 60000, making it easy to trace.

Alarm and fault records

The system is equipped with a dedicated historical database that provides historical alarm records and historical fault records. Users can access, query, and print them at any time through the report interface. Users with advanced permissions or above can delete records one by one or all.

Alarm printing

The monitoring equipment is equipped with a micro printer, which can automatically/manually print alarm and fault information. Support setting the interface to automatically print information when an alarm/fault occurs.

Historical data trend curve

The system supports curve based querying of residual current and temperature data stored in history, and the query time interval and circuit can be dynamically set. The interface can reflect in real-time the range of residual current or temperature changes within any given time period.

Status information display

The system can display various current status information in real time (power supply status, equipment fault status, alarm status, and the working status of all communication devices) synchronously with the monitoring device indicator lights.

System fault self check

The monitoring equipment displays the real-time operation status of various internal functional modules and has fault self diagnosis function. At the same time, it displays the cause of the fault in real-time on the system interface and judges the communication status of detectors in various areas in real time, intelligently self checking the faults of the entire system.

User rating management

The system is divided into three levels of permission management, and different operations require corresponding permission levels to operate, in order to prevent misoperation and illegal entry.

System operation information

The system has an independent information window that records all operational information of the device after self startup, facilitating comprehensive judgment of the current status of the operating system.

CN

CN EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  ar

ar  vi

vi  tr

tr  th

th