Dongfeng Honda Automotive Parts Co., Ltd. was established on December 23, 1994, jointly funded by Dongfeng Motor Corporation and Honda Technology Research Industry Co., Ltd. It was officially put into operation on November 30, 1995. The company's current factory covers an area of approximately 240000 square meters. In August 2014, the groundbreaking ceremony for the 420000 square meter new factory ("Dongben Integration" project) was held in the Daya Bay Emerging Industry Park, marking a new stage in the company's development. In 2018, the company will build a modern green factory that integrates casting, forging, and machining.

The company mainly produces key components for Honda series sedan engines and chassis, including connecting rods, camshafts, crankshafts, cylinder liners, front and rear steering knuckles, front and rear brake discs, wheels, etc. It is mainly used as a supporting product for Honda series models produced by Dongfeng Honda Motor Co., Ltd., Dongfeng Honda Engine Co., Ltd., GAC Honda Motor Co., Ltd., Honda Motor (China) Co., Ltd., and overseas companies. It is an important component production base for Honda passenger cars in China.

The company has always been committed to providing products and services that exceed customer and social expectations, winning the trust of customers and society, actively improving the corporate governance system, strictly controlling product quality, reducing operational risks, and strengthening safety management. Since its establishment, it has successively obtained ISO9001 quality management system, ISO14001 environmental management system, OHSAS18001 occupational health and safety management system, and national safety and quality standardization first-class enterprise.

For over 20 years, the company has been committed to creating a unique corporate culture under the guidance of the parent cultures of Dongfeng and Honda, enhancing the cohesion and sense of belonging of all employees. Under the guidance of the cultural concept of "respecting individuality and harmonious coexistence", the company will continue to move towards the grand goal of "becoming an enterprise that is expected to exist and develop sustainably by society.".

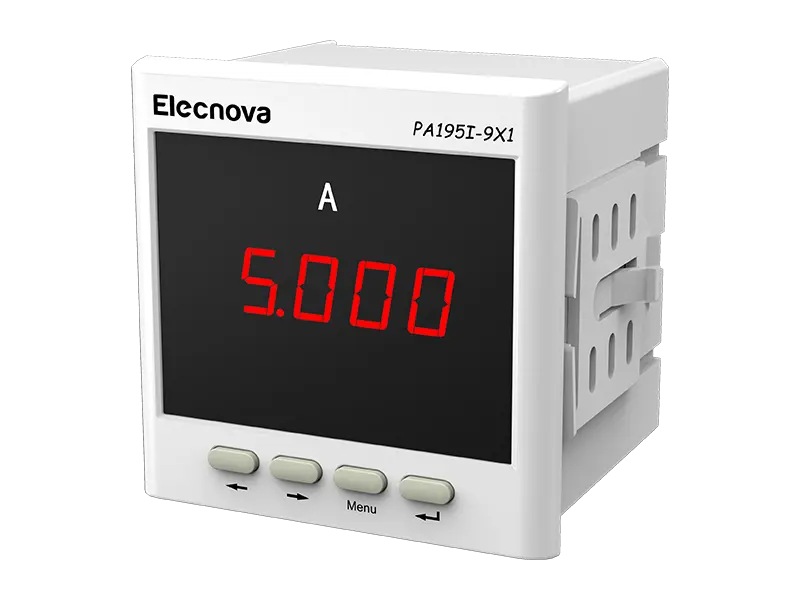

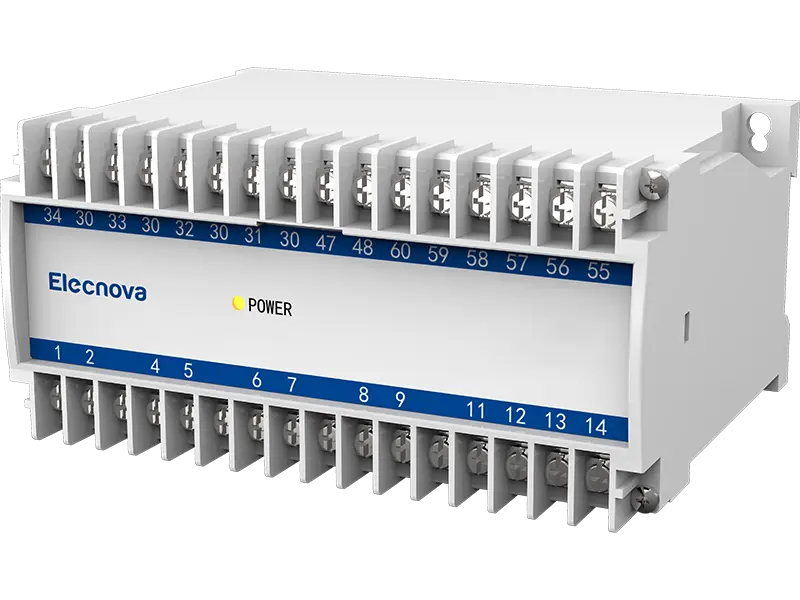

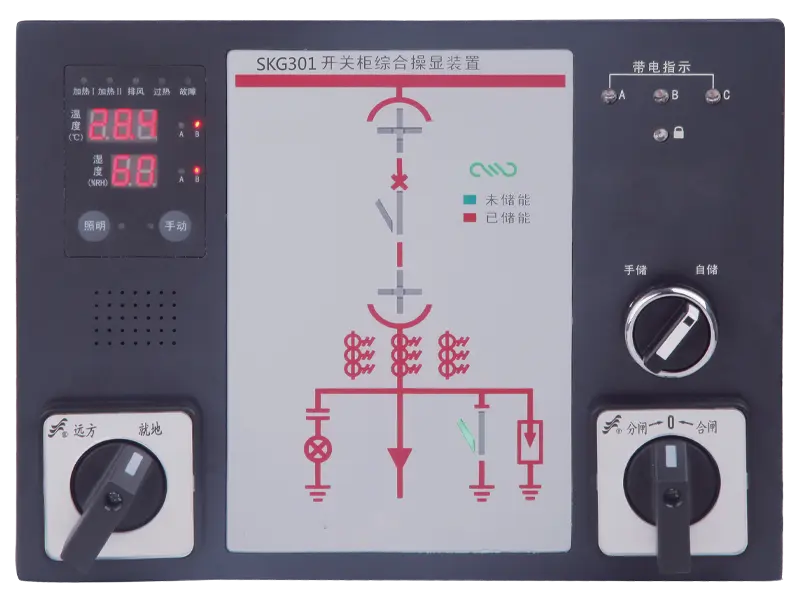

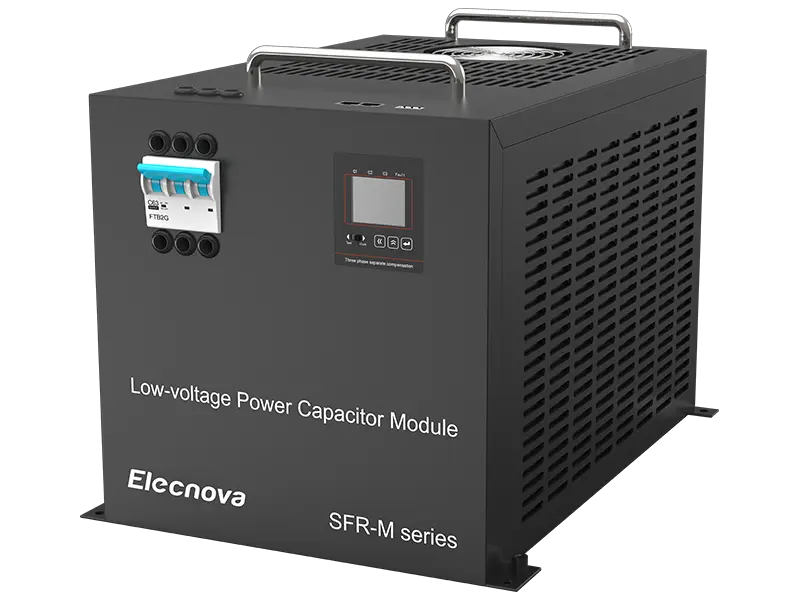

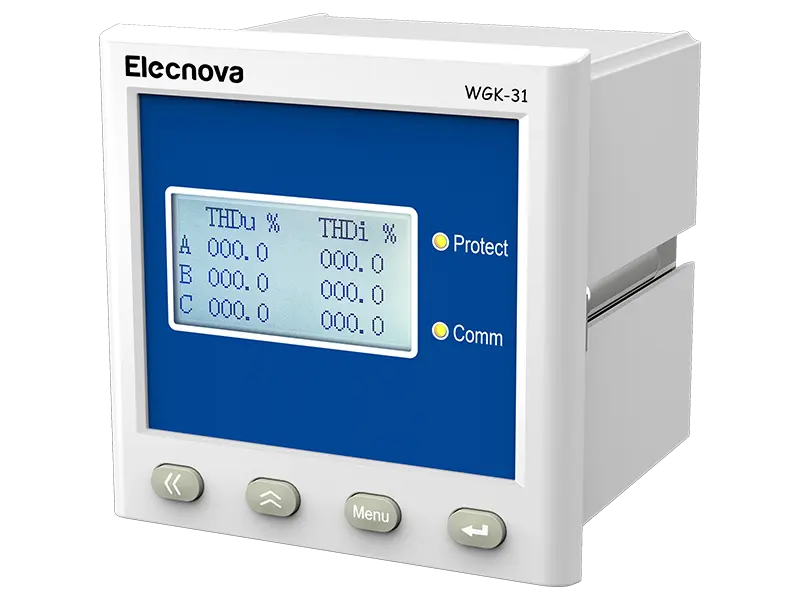

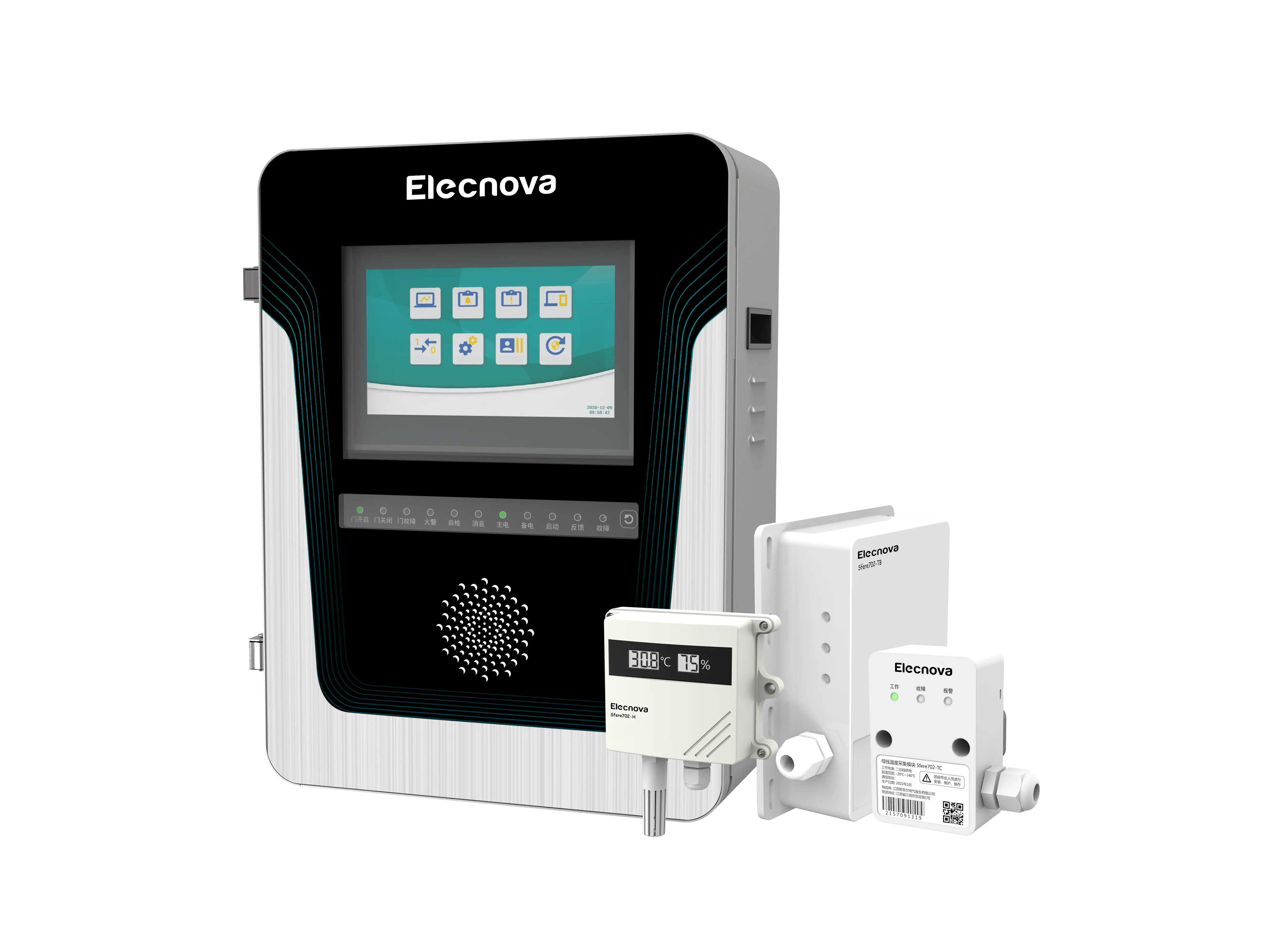

Jiangsu Elecnova Electric Co., Ltd. undertakes the intelligent monitoring and energy management system project, which consists of three parts: intelligent power monitoring system, energy management system, and electrical fire monitoring system. These three parts are three relatively independent systems, each with its own independent hardware and running software. The intelligent power monitoring system, energy management system, and electrical fire monitoring system can achieve data sharing through network connection. It can automatically collect and intelligently manage the electrical energy information of various measuring points in the entire plant's switchgear and distribution room, ensuring that the distribution network operates in a safe, reliable, high-quality, and efficient optimal state. It can achieve remote measurement, control, and management of the distribution network, and meet the needs of electricity safety, energy management, and energy conservation and consumption reduction. By collecting and analyzing data on water, electricity, and gas, the energy consumption of the user end is segmented and statistically analyzed to form intuitive data and charts, achieving remote meter reading function and comprehensive energy management covering energy plan management, energy performance management, energy balance management, energy statistical analysis reports, and other functions. By monitoring parameters such as residual current and load current in the circuit, alarm and monitoring of the protected electrical circuit can be achieved, and it can be uploaded to the fire monitoring system for centralized control and management.

CN

CN EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  ar

ar  vi

vi  tr

tr  th

th